Please Wait

This won't take a moment...

If you follow an old diesel vehicle that's accelerating away, you know what’ll happen – a small black cloud of soot will puff out of the exhaust. That'll soon be a thing of the past though because, thanks to their new DPF technology, modern diesel vehicles are cleaner than ever before.

The DPF is a filtration system, located within the exhaust system, which filters out harmful soot particles from the exhaust gases. The maintenance-free filter normally consists of a silicon carbide core, perforated by microscopic channels. The exhaust gas passes through the channel walls, on which the particulates collect.

No, the DPF is entirely self-cleaning, a process which is controlled by the engine management system and pressure and temperature sensors which detect when the filter must be cleaned.

The exhaust temperature is then increased by deliberate multiple fuel injections into the engine, raising the temperature of the DPF to 600°C, which burns the soot particles without leaving any residue.

The regeneration process takes place periodically, under normal driving conditions, without the driver noticing that it’s in progress. Vehicles that spend much of their time on short trips or in urban environments may require a longer journey at higher speeds to complete the regeneration cycle – in these instances a dashboard reminder light will inform the driver when this is required.

If the driver ignores the warning light and waits too long to operate the vehicle at a higher speed over a longer distance, the DPF may not regenerate properly. If this continues it can damage the DPF completely, meaning it will need to be replaced at an authorised garage.

If you think the Diesel Particulate Filter in your vehicle is damaged and needs replacing visit or call your nearest Pentagon Service Centre for advice.

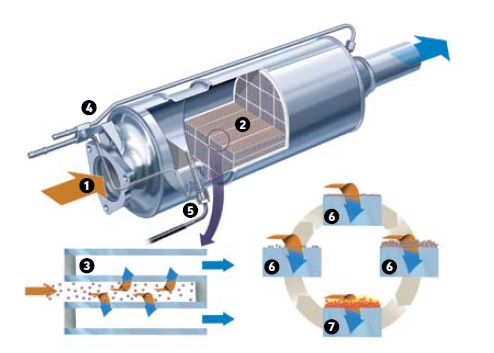

Upon entering the DPF (1) the exhaust gases are directed through the silicon carbide core (2) before being allowed to continue through the exhaust system.

Upon entering the DPF (1) the exhaust gases are directed through the silicon carbide core (2) before being allowed to continue through the exhaust system.

The construction of the core (3) offers a large surface area to the passing exhaust gases, giving a plentiful storage volume for collected soot.

The soot volumes are monitored at all times by pressure and temperature sensors (4/5), which feed information to the engine management system to determine when the filter requires regeneration.

When the soot levels (6) have reached their allowed limit, the regeneration process is initiated (7), in which the exhaust gas temperature is raised to 600°C, by multiple fuel injections, in order to burn off the soot particles.

Chester, Flintshire, CH5 2QJ

Derby, Derbyshire, DE22 4NB

Glasgow, Lanarkshire, G51 4SX

Gloucester, Gloucestershire, GL2 5FD

Manchester, Lancashire, M24 1SW

Wrexham, Wrexham, LL14 4DP

Grimsby, North East Lincolnshire, DN31 2TG

Halesowen, West Midlands, B63 2RL

Glasgow, Lanarkshire, G51 4SX

Derby, Derbyshire, DE22 4NB

Glasgow, Lanarkshire, G51 4SX

Sandycroft, Deeside, CH5 2QE

Manchester, Greater Manchester, M17 1HG

Lincoln, Lincolnshire, LN6 7QY

Pentagon Citroen Lincoln

Pentagon Citroen Lincoln

Lincoln, Lincolnshire, LN6 7QY

Pentagon Citroen Loughborough

Pentagon Citroen Loughborough

Loughborough, Leicestershire, LE11 1NE

Pentagon CUPRA Huddersfield

Pentagon CUPRA Huddersfield

Huddersfield, West Yorkshire, HD2 1AA

Lincoln, Lincolnshire, LN6 7QY

Rochdale, Lancashire, OL11 1TQ

Pentagon Ford Runcorn

Pentagon Ford Runcorn

Runcorn, Cheshire, WA7 2XP

Pentagon Ford St. Helens

Pentagon Ford St. Helens

St. Helens, Merseyside, WA9 5AD

Pentagon Ford Warrington

Pentagon Ford Warrington

Warrington, Cheshire, WA2 7NY

Pentagon Kia Sheffield

Pentagon Kia Sheffield

Sheffield, South Yorkshire, S9 4WA

Pentagon Mazda Lincoln

Pentagon Mazda Lincoln

Lincoln, Lincolnshire, LN6 7QY

Lincoln, Lincolnshire, LN6 7QY

Pentagon Nissan Barnsley

Pentagon Nissan Barnsley

Barnsley, South Yorkshire, S75 1LR

Pentagon Peugeot Barnsley

Pentagon Peugeot Barnsley

Barnsley, South Yorkshire, S75 1LR

Pentagon Peugeot Burton Upon Trent

Pentagon Peugeot Burton Upon Trent

Burton-on-Trent, Staffordshire, DE13 0DF

Pentagon Peugeot Lincoln

Pentagon Peugeot Lincoln

Lincoln, Lincolnshire, LN6 7QY

Pentagon Peugeot Loughborough

Pentagon Peugeot Loughborough

Loughborough, Leicestershire, LE11 1NE

Pentagon Peugeot Scunthorpe

Pentagon Peugeot Scunthorpe

Scunthorpe, North Lincolnshire, DN16 3RL

Lincoln, Lincolnshire, LN6 7QY

Pentagon Renault Loughborough

Pentagon Renault Loughborough

Loughborough, Leicestershire, LE11 1NE

Pentagon Renault Rochdale

Pentagon Renault Rochdale

Rochdale, Lancashire, OL11 1TQ

Pentagon SEAT Huddersfield

Pentagon SEAT Huddersfield

Huddersfield, West Yorkshire, HD2 1AA

Pentagon SEAT Nottingham - Chilwell

Pentagon SEAT Nottingham - Chilwell

Nottingham, Nottinghamshire, NG9 4AJ

Pentagon SEAT Oldham - Park Road

Pentagon SEAT Oldham - Park Road

Oldham, Lancashire, OL8 1DB

Pentagon SEAT Scunthorpe

Pentagon SEAT Scunthorpe

Scunthorpe, North Lincolnshire, DN16 3RL

Pentagon Vauxhall Burton Upon Trent

Pentagon Vauxhall Burton Upon Trent

Burton-on-Trent, Staffordshire, DE13 0DF

Pentagon Vauxhall Derby

Pentagon Vauxhall Derby

Derby, Derbyshire, DE21 6HB

Pentagon Vauxhall Loughborough

Pentagon Vauxhall Loughborough

Loughborough, Leicestershire, LE11 1NE

Pentagon Vauxhall Middleton

Pentagon Vauxhall Middleton

Manchester, Lancashire, M24 1SW

Pentagon Vauxhall Oldham - Chadderton Way

Pentagon Vauxhall Oldham - Chadderton Way

Oldham, Lancashire, OL1 2QL

Pentagon Vauxhall Rochdale

Pentagon Vauxhall Rochdale

Rochdale, Lancashire, OL11 1TQ

Pentagon Vauxhall Sheffield

Pentagon Vauxhall Sheffield

Sheffield, South Yorkshire, S9 4WA

Derby, Derbyshire, DE22 4NB

Stoke-on-Trent, Staffordshire, ST6 2DE

Glasgow, Lanarkshire, G51 4SX

Nottingham, Nottinghamshire, NG9 2JR

This won't take a moment...

If you have a query relating to Discretionary Commission Agreements please email customer.care@pentagon-group.co.uk However, please note that if your query related to a purchase more that 7 years ago we will no longer hold any details due to our data retention policy.

This won't take a moment...